PETG Quick Start Guide

Quick Start Guide:

PETG Filament

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture plastic drink bottles. This semi-rigid material is highly impact and chemically resistant, but its surface is slightly softer than other materials. PETG benefits from great thermal properties, allowing it to cool efficiently with almost negligible warpage making it great for tough parts when 3D printing with a setup without an enclosure.

The mechanical and visual properties of PETG make it a highly useful material. As opposed to beginner-friendly materials such as PLA and PLA+, PETG prints best within a tighter tolerance range of settings, making it slightly less forgiving.

For more information on what PETG is and what it’s good for, check out our Introduction to PETG.

Pros |

Cons |

|||||

|---|---|---|---|---|---|---|

| ✔️ | Great chemical and weather resistance | ❌ | Wet PETG filament can produce parts with fine stringing on the part surface | |||

| ✔️ | Sticks well to the bed with negligible warping | |||||

| ✔️ | Odourless while printing | |||||

Hardware Requirements

|

Enclosure |

Heated Bed |

Hardened |

Fan |

|

|

|

|

|

| ✔️ | ✔️✔️ | ✖️ | ✔️✔️ |

|

Fume |

Direct |

High Temp |

Filament |

|

|

|

|

|

| ✔️ | ✖️ | ✖️ | ✔️ |

Printing Settings

As opposed to printing in other materials, with PETG you will have to pay greater attention to the following settings when 3D printing in PETG:

Extruder Temperature

-↓ Extruder Temperature ↓ Stringing - Will decrease at temperatures <220°C as the molten filament will have a higher viscocity, leading to a neater print. ↓ Oozing - See above. ↑ Underextrusion - Can happen at temperatures of <220°C as your printer simply can't melt the filament fast enough to keep up with the filament feed rate. Our tip: Before adjusting your extruder temperature any lower than <220°C, try adjusting your retraction, coasting and travel speed. |

220°CsSet your extruder temperature to 220°C. Increase the printing temperature if you are experiencing underextrusion or if your extruder gear is slipping. 🛈

|

+↑ Extruder Temperature ↑ Stringing - Increases at temperatures <240°C as the molten filament will have a lower viscocity, flowing more freely. ↑ Oozing - See above. ↓ Surface Resolution- At temperatures of <240°C leading to sloppy layers and an increase in artifacts like stringing and oozing. |

Bed Temperature

-↓ Bed Temperature ↓ Part Adhesion - Too little heat in the bed will cause your part to cool to quickly, curl and dislodge from the bed. |

70 - 80°CsSet your bed temperature to 80°C for your first layer to ensure your first layer sticks to the bed and 75°C for the rest of the print. 🛈

|

+↑ Bed Temperature ↑ Part Deformation - Too much heat will cause your part to melt into the bed, deforming the bottom layers. |

Fan Speed

-↓ Fan Speed ↑ Part Strength - Slows the cooling rate of each layer being printed. This gives the part more time to bond to the preceeding layer, resulting in increased interlayer adhesion and part strength. Helps remedy part delamination problems. PETG can be printed with fan speed set to 0%. ↓ Surface Resolution - Decreasing the fan speed will result in your PETG staying more molten for longer. This can result in sloppy layer lines and an increase in artifacts like stringing and burnt looking spots resulting from oozing. |

50%Start at 50% fan speed for a good balance between part strength and surface resolution 🛈

|

+↑ Fan Speed ↓ Part Strength - Increases the cooling rate of each layer being printed. This gives the part less time to bond to the preceeding layer, resulting in less interlayer adhesion and a decrease in part strength. |

Print Speed

-↓ Print Speed | ↑ Print Time ↑ Layer Adhesion - Gives your layers more time to bond, increasing interlayer adhesion. ↑ Part Deformation - Too much thermal energy may be pumped into your part, slowing down the cooling and resulting in sloppy layers ↓ Travel Speed | ↑ Print Time ↑ Stringing - More time spent travelling results in more molten material leaking out of the nozzle of your printer leading to more stringing |

30 - 50mm/sPrint Speed: Start at 50mm/s and only increase the print speed if you are comfortable with the print quality. Printing your first layer at 25mm/s will help keep your part stuck to the bed. 🛈

|

+↑ Print Speed | ↓ Print Time ↓ Layer Adhesion - Gives your layers less time to bond, decreasing interlayer adhesion. Aim to keep print speeds under 60mm/s for best results. ↑ Extruder Skipping - Can occur when the printer can't melt and print filament fast enough ↑ Travel Speed | ↓ Print Time ↓ Stringing - Less time spent travelling results in less molten material leaking out of the nozzle of your printer decreasing stringing |

Retraction Distance

-↓ Retraction Distance ↑ Stringing -Shorter retraction distances causes a smaller a drop in the pressure inside the nozzle. With distances less than 3mm, it may not be enough to stop molten filament from leaking out of your nozzle. ↓ Oozing - See above. |

3 - 6mmFor Bowden systems: Start with a retraction of 3mm. Increase retraction to 4mm if needed. This distance may be higher if you have a longer bowden tube. For Direct Drive systems: Start with a retraction of 1mm. Increase retraction distance to 2mm if needed. Our Tip: Tune retraction distance up/down by 0.5mm increments. Aim to keep the distance between the 0.5 - 6mm. 🛈

|

+↑ Retraction Distance ↓ Stringing - Causes a larger a drop in the pressure inside the nozzle, stopping more filament from leaking out of your nozzle. ↓ Oozing - See above. ↑ Underextrusion - Excessive retraction can cause a delay before your nozzle resumes printing causing underextrusion. Our tip: If your retraction distance is at the upper limit, try adjusting your retraction speed, coasting & travel speed. |

Retraction Speed

-↓ Retraction Distance ↑ Stringing - Lower retraction speeds cause a smaller drop in the pressure inside the nozzle which may not be enough to stop filament from leaking out of your nozzle. ↑ Oozing - See above. |

45mm/sStart with a retraction speed of 45mm/s. Our Tip: Increase retraction speed by 5mm/s increments until you notice diminishing in returns in stringing and oozing. 🛈

|

+↑ Retraction Speed ↓ Stringing - Causes a larger a drop in the pressure inside the nozzle, stopping more filament from leaking out of your nozzle. ↓ Oozing - See above. ↑ Filament Slip - Excessivly high retraction speeds can cause the feed gears to slip, causing extrusion problems. Our tip: If your retraction distance is at the upper limit, try adjusting your retraction speed, coasting & travel speed. |

|

The internet is filled with conflicting information regarding different settings. It’s critical to understand not all 3D printers are built the same. This makes giving exact recommendations for settings difficult as settings for one printer may not necessarily carry over to others. |

|---|

Best Practices

In order to print PETG successfully, having the correct the hardware setup and temperature settings outlined above are only half the battle. Here are some best practices to ensure reliable PETG prints.

+ Start with the lowest temperature

When printing in PETG, many problems related to print quality arise from printing too hot. Start printing PETG at the lowest temperature recommended by your manufacturer. By doing this you'll ensure you begin printing at the most optimal temperature.

We recommend printing at 220°C with our PETG.

+ Calibrate retraction settings to reduce stringing

PETG tends to become runny when it is brought up to printing temperature. As your extruder moves around, molten PETG can leak out of your printer's nozzle and end up on your 3D printed part. This results in fine hairs and strings building up on the outside surface of your PETG print.

This can be alleviated by calibrating your retraction settings.

We recommending starting with a retraction speed of 45mm/s and a retraction distance of between 3-6 mm for a Bowden setup or 1-2mm for a direct drive printer.

For more in-detailed tips check out our PETG Ultimate Printing Guide.

+ Enable coasting settings to reduce blobs

When printing, PETG tends to continue extruding even after the printer has stopped extruding.

This leads to excess material commonly called zits and blobs that build up on your print, reducing print quality. Sometimes this material can even build up to an extent where it can cause a print to fail.

Enabling coasting tells your printer to stop extruding just before the end of a print layer. This ensures less material oozes out of the nozzle during the travel move that occurs immediately after the print move. Set your costing volume to the cubed value of your nozzle diameter and a volume before coasting of around double your nozzle diameter. (i.e. A coasting volume of 0.064mm³ and a 0.8mm³ volume before coasting for a 0.4mm diameter nozzle)

For more in-detailed tips check out our PETG Ultimate Printing Guide.

+ Increase travel move speed

PETG tends to continue oozing out of the nozzle between print moves.

Increasing the printer's travel speed between extrusion moves decreases the likelihood the nozzle spends depositing unwanted material on your print.

Increased Travel Speeds of 150mm/s and greater will ensure your printer's nozzle spends less time oozing between print moves.

For more in-detailed tips check out our PETG Ultimate Printing Guide.

+ Keep Your Filament Dry

PETG is hygroscopic material meaning it will absorb moisture from the surrounding air. This absorbed moisture in the filament is not a problem once the part has been printed but does present a problem during printing and can result in a 3D printed part with:

- Weaker interlayer bonding

- Stringing and fine hairs developing on the print

- Poor surface resolution

As such, keep your filament stored in a dry environment with, like in an airtight bag or a box filled with desiccant packs. This should preserve the filament and prevent it from absorbing too much moisture.

If your filament is already wet, then you can dry it out with an oven set at around 60 °C. Leave the spool in the oven for a few hours while the moisture is cooked out.

For more in-detailed tips about filament storage check out our Filament Storage & Handling Guide.

+ Use Hairspray or Glue as a Release Agent

Usually other 3D printing materials have trouble sticking to print beds and need a thin spray of hairspray or glue stick to act as an adhesive. PETG is the opposite - it sticks so well that it can even tear chunks out of your build surface.

When printing in PETG applying a thin layer of hairspray or glue is surprisingly also an effective solution for PETG parts that stick too well to the build plate. Once applied the added layer acts as a release agent preventing the PETG from damaging your build surface if you are printing on anything other than a metal print bed.

Use a release agent if your printer's bed is:

- Glass

- PEI or PEI coated

- Polymer based (Buildtak or similar)

For more in-detailed tips check out our PETG Ultimate Printing Guide.

+ Allow for Additional Z-Offset Distance

Unlike PLA and ABS, PETG needs a little extra room to be lain down as it exits the nozzle. Allowing for an additional Z-offset of 0.02mm can make a difference when printing in PETG.

PETG doesn't only stick really well to the bed, it sticks very well to itself as well. While this makes for solid 3D printed parts, it can make removing support material a tricky prospect.

For clean support removal and neat interface layers (the layers linking the support to your 3D print) allow for a little extra Z offset to ensure the support doesn't fuse to the print.

For more in-detailed tips check out our PETG Ultimate Printing Guide.

Pro Tips

+ Adjust One Setting At A Time

Dialling in your PETG print settings can be a little tricky and sometimes requires the manipulation of multiple settings to eliminate the dreaded problems of stringing and oozing. Try tackling the settings tweaks using the tips outlined above in the following order adjusting one setting at a time.

- Printing Temperature

- Travel Speed

- Retraction

- Coasting

- Fan Speed

+ Adhesion Hack

Try disabling your part cooling fan and printing 5-10°C for the first few layers of the print to keep the part stuck to the print bed.

For a more in-detail look at the best practices when 3D printing in PETG, check out our next guide in this series PETG Filament Ultimate Printing Guide.

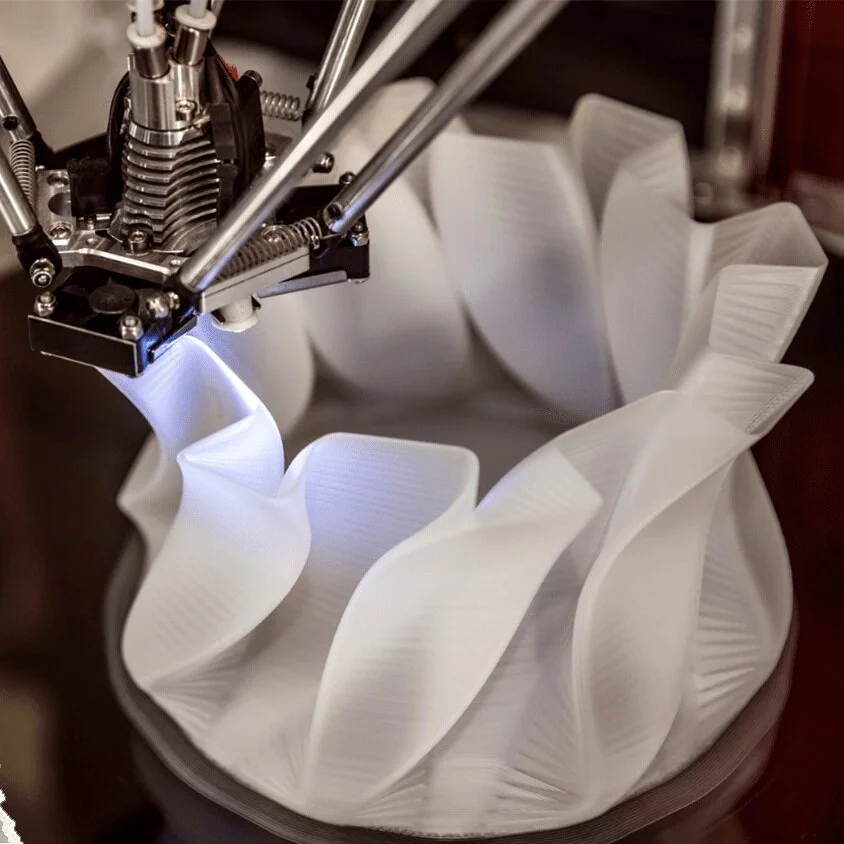

Applications

Outdoor Applications

Live Hinge Parts

Snap Fit Components

![The General Guide to 3D Printing [2021]](https://images.squarespace-cdn.com/content/v1/5731cadf7c65e4d72b3b98d1/1605047959391-2ZHXJ6OF7ZAOUX9N5RH2/16.jpg)

![PETG Ultimate Filament Printing Guide [2022]](https://images.squarespace-cdn.com/content/v1/5731cadf7c65e4d72b3b98d1/1583218701039-R9J9CVFDM740CNIN13V2/image-asset.jpeg)

What are the best settings for 3D printing in HIPS? Find out in our Quick Start Guide which contains the best settings AND explanations for printing in HIPS.