Dry Tech 3D Printing Filament Dry Cabinet 80L

Dry Tech 3D Printing Filament Dry Cabinet 80L

FILAMENT DRY CABINET

Dry Tech’s 3D printing filament dry cabinet is an efficient and compact filament dehydration and storage solution specially designed for 3D printing applications.

The 80L Filament Dry Cabinet Features:

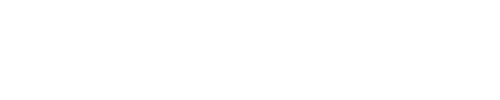

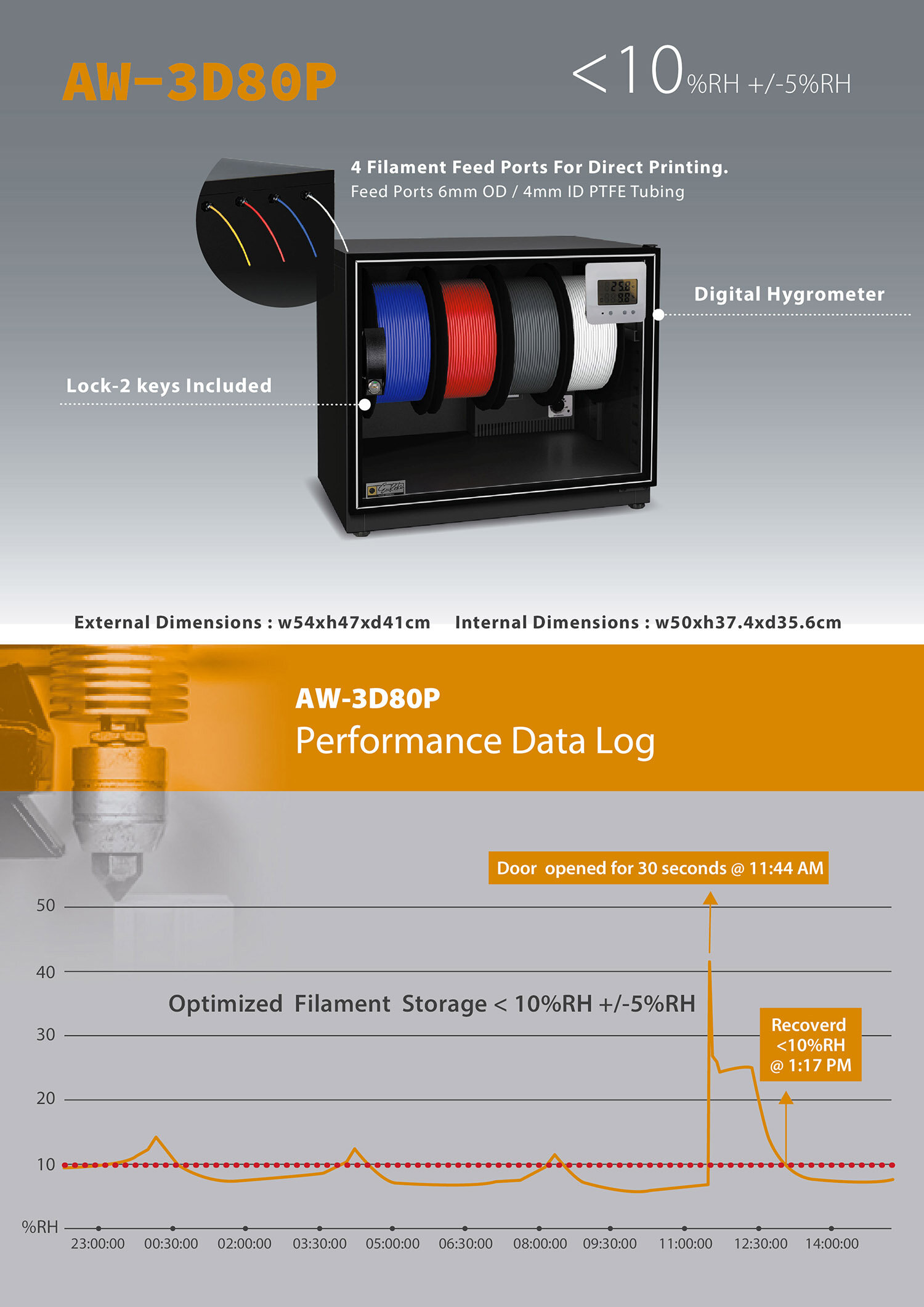

Industry leading 10%±5% low humidity storage

Powered operation eliminating the need for consumable desiccant or Nitrogen (N2)

Dries without heating for warp free filament dehydration

Fast 2-hour recovery to target humidity

Integrated digital hygrometer for active monitoring of humidity

4 filament feed ports allowing for direct printing from the cabinet

Holds up to 9 x Standard Print Co. 1kg ECO Spools on integrated, adjustable hanger

Each unit is individually lab calibrated, tested and certified before shipping

By keeping your filament in a constant 10%±5% low humidity environment, the Dry Tech Filament Dry Cabinet keeps even your most hygroscopic demanding filaments like Nylon, PVA and Carbon-Fibre Composite filament in optimum printing condition.

Featuring laboratory grade, heat-less desiccating technology, even fully saturated filament can be dried, bringing old filament back to printing condition without fear of warping that can occur when “baking” filament using cheaper, heat-based systems.

Leave material wastage and poor-quality prints behind with Dry Tech’s Filament Dry Cabinets.

Compatibility:

Dry Tech’s Filament Dry Cabinet 80L internal dimensions are W 54cm x H 47cm x D 41cm and is compatible with all 3D printer filament spools up to 41cm in diameter.

Features

Perfect Storage Conditions - Perfect Part Strength

Designed from the ground up for 3D printer filament storage, our dry cabinet utilises a unique combination of molecular sieves and control shutters, allowing it to maintain an ultra-low humidity level of <15%RH - the optimal condition for 3D printer filament storage, ensuring ultimate strength of your printed parts. Other drycabinets, such as camera storage cabinets, typically keep the filament at >25%RH - far from the optimal level for 3D printer filament.

Heat Free Dissication - Ultimate Print Accuracy

Our cabinets use regenerative molecular sieves, not heaters, to create a warp- and melt-free, ultra-dry environment for filament storage. This innovative solution removes the need for setting timers or temperatures, making it simple to dry and store your filament on autopilot - without running the risk of heat-distorting your filament.

Direct Printing - 100% Uptime

Four, specially designed PTFE coupler ports allow you to feed four different spools/materials directly into your printers from the dry box. This ensures your filament is kept at optimal condition for the entire duration of your print and does not compromise the internal humidity of the cabinet. Without having to open and close the door every time to print, your filament is kept at a constant level of dryness and ready to print whenever you are.

Consumable Free - Fully Automated

Dry Tech’s innovative, regenerative molecular sieves eliminate the need for consumables such as single use desiccant. The sieves remain infinitely regeneratable for the life of the printer, resulting in a unit that is far more energy efficient than traditional heat based condenser models. By drying the filament passively and storing it in

Filament Regeneration - Zero Filament Wastage

Dry Tech’s industry leading, ultra-low humididty levels mean that even your most hygroscopically demanding materials such as Nylon, PEEK and PEKK can be kept at optimal printing condition. Fully saturated filament that has been left out can even be regenerated and brought back to printing condition, decreasing filament waste due to spoilage.

Lab Developed & Tested - Science Backed Performance

Lab developed, manufactured and calibrated, each Dry Tech Filament Dry Cabinet is manufactured by a global leader in dessication technology. Each cabinet is individually tested and certified before being shipped gauranteeing industry leading performance every single time.

Tech Specs

| Application | Automated Desiccating Cabinet For 3D Printer Filament | Internal Dimensions | 500 W X 374 H X 374 D mm | |

|---|---|---|---|---|

| Humidity Range | ≤10% RH ±5%RH | Product Dimensions | 540 W X 470 H X 410 D mm | |

| Capacity | 81L | Shipping Dimensions | 620 W X 510 H X 580 D mm | |

| Recovery time | 2 Hours to <10% RH | Shipping Weight | 16.5 KG | |

| Hygrometer Type | Digital Thermal Hygrometer Calibrated for <15%RH | Construction | Anti-Static Coated Metal Cabinet With Glass Door | |

| Feed Ports | 4x 6mm OD / 4mm ID PTFE Couplers | Country of Manufacture | Taiwan (ROC) | |

| Lock Type | Turn Key Lock - 2 Keys Included | Voltage Input | 230 V | |

| Spool Capacity | 12-15 | Power Consumption | 12 W | |

Technical Documentation

How do Dry Tech Cabinets Work?

Dry Tech Dry Cabinets utilise multi-porous molecular sieves and a two stage 1) absorption and 2) exhaust process to desiccate (dry) the air inside the cabinet. This process is far more effective, power efficient and safe for your filament than comparable heat based dissociation methods.

What is a molecular sieve?

Think of them as a highly absorbent mineral sponge. Molecular sieves are materials that are made up of a complex matrix of uniform pores (very small holes). The pores in the molecular sieves used for our Dry Tech Dry Cabinets are so small in fact that they are about the size of a single water molecule. Due to the unique matrix structure of these sieves, capillary forces and the Wan der Waals forces actively pull water molecules into the molecular sieve, drying the surrounding area.

Stage 1: Dehumidifier Core Unit Adsorption Stage

During the adsorption stage, the dehumidifier core unit's valve doors open on the inside and seals from the outside. This allows moisture inside the dry cabinet to be naturally adsorbed into the multi-porous molecular sieves in the core unit. During this stage, the core unit performs its desiccating function without any power consumption and will continue to desiccate even when power supply is interrupted. Operational light indicators inside the cabinet will remain off during this time.

Stage 2: Dehumidifier Core Unit Exhaust Stage:

The core unit valve doors automatically seals inside the dry cabinet and open vents outwards to exhaust & expel the moisture absorbed from inside the Dry Box. During this stage, operational indicators will be on. Moisture adsorbed by the multi-porous molecular sieves is expelled by the drying unit and the core unit is automatically regenerated for moisture adsorption. There are no water tanks to empty, desiccant bags & packs to replace, or any other maintenance required by the user. Simply plug in the power cord, set the desired RH level and the Dry Tech Cabinet will begin its dehumidifying operation cycle. The core unit performs the moisture adsorption process without any power required meaning desiccation will continue even in the event of a power outage.

Why do I need to keep my filament dry?

3D printer filaments are hygroscopic, meaning they will absorb moisture from the surronding air. This process begins the moment the filament is removed from its protective packaging.

This process can take a matter of days like in the case of PLA, PETG and ABS or hours like in the case of Nylon and PVA.

When the saturated filament is extruded, the moisture inside the filament, heats up, boils and expands as steam inside the molten filament. The steam forms bubbles inside the molten filament.

Printing with wet filament can cause:

Significantly lower the part mechanical strength

Poor surface resolution

Poor layer adhesion

Stringing

FAQ’s

+ Why are Dry Tech Cabinets better than comparable 3D filament dryboxes systems?

There are currently two main types of filament drying technologies on the market.

Unpowered Desiccant Dry Boxes

These systems use consumable desiccant in the form of silica gel beads or other, single-use desiccating material to dry the air inside a sealed, airtight container.

Pros:

- Low cost - Cheap and simple to setup as any airtight container and enough desiccant can constitute a drybox.

Cons:

- Limited Uses - Desiccants stop working when they are fully saturated. This limits the maximum amount of water they can absorb before needing to be replaced. This effectively means your desiccant powered drybox becomes less effective the more you open your drybox. Adding PTFE ports for direct printing from your drybox introduces more humid outside air into your box meaning you'll have to switch out your desiccant even sooner.

- Limited Performance - Desiccants like silica gel are only so hygroscopic. Even in sealed dryboxes in ideal conditions, silica gel struggles to maintain a relative humidity (RH) level of < 30%RH. This is quite far off the 15%RH necessary to keep your filament in optimal printing condition, let alone keep even more hygroscopic filament like Nylon, PEEK and PEKK dry.

Heat powered systems

These systems often take the form of "filament dryboxes" that integrate a heating element into a non-airtight chamber designed to hold a spool of filament. When powered on, these dryboxes heat the air and filament to a theoretical 20RH% in order to expel moisture.

Pros:

Faster drying - Heating both the filament and air result in fast desiccation.

Small Footprint - Often holding a single spool these units are compact and great for desktops.

Cons:

Not Intended For Storage - As these systems are powered using heating elements, once the heat stops, so does the drying. These systems are only intended to be turned on for a few hours meaning a seperate storage solution is required. As these dryboxes are not designed to be airtight (so that moisture can be expelled during the heating process) moisture finds its way in quickly when the unit is powered off.

Energy intensive - The heating elements used to power these units are energy intensive with energy consumption even matching some 3D printers.

Requires Attention - With dehydration cycles lasting 4-12 hours, manual intervention is required to transfer dried filament into a drybox for storage.

Possible Filament Damage - Inconsistent heat distribution or heating the filament too fast can cause stress fractures in the filament, causing already saturated and brittle filament to snap.

Possible Filament Warping - Heating of the chamber at temperatures close to or above the filament's glass transition temperature can cause the filament to soften and deform, ruining the filament's roundness and accuracy via over/under extrusion.

+ Can I print 2.85mm filament from the Dry Tech Cabinet?

Yes. The Dry Tech Cabinet uses four universal PTFE couplers that will accept PTFE tubing designed for both 1.75mm and 2.85mm diameter filaments. Our Capricorn XS 1.75mm Bowden Tubes (4mm OD) for example will fit as well as well as Capricorn's 2.85mm (6mm OD) Tubes.

+ Does the Dry Tech Cabinet use any consumables?

No. The Dry tech cabinet uses permanent molecular sieves that are regenerated upon each exhaust stage. They are designed to last for the entire lifespan of the cabinet.

+ Will the Dry Tech Cabinet keep filament spools from other manufacturers dry?

Absolutely - If it fits, it will dry. Dry Tech Cabinets will keep anything that fits inside dry as long as the door remains closed for more than 2 hours.

+ I mainly print in PLA/PETG/ABS, do I need a Dry Tech Cabinet?

Probably. While standard filaments like PLA/PETG/ABS are ready to print right out of the packet and do not require baking, they are still hygroscopic and will readily absorb moisture from the air. If you are not using the whole roll in a single print, you will need a filament storage solution if you want your filament to perform to the same standard again.

If you don't have many spools open at any one time, simple zip-lock style bags or sealable containers with desiccant may be sufficient. If you have more than a few spools or intend to store your filament for more than a few weeks, a Dry Tech Cabinet may be the solution for you.

(See: "Why are Dry Tech Cabinets better than comparable 3D filament drybox systems?" above)

Shipping & Sales Info

All our Dry Tech appliances come with a 12 month, Australian based, parts warranty and a 24 month support warranty. See terms and conditions for more details.

We ship all to all around Australia. If you are not located in Australia contact us for a shipping quote as we still ship to your country.

Shipping is calculated during checkout, before you confirm your order. Depending on your location shipping time may vary and will be indicated during the checkout process. We do not offer an overnight shipping option.

For international customers, duties and taxes are assessed by your local customs authority upon importation and are the responsibility of the customer. These taxes and duties are not included with your purchase.

For orders placed within Australia, GST is included in the sale price.

Require a quote, purchase order or pay via direct deposit? contact us with the details of your order and we’ll generate an invoice or quote for you.

Looking to kit out a space with multiple units? We offer discounts on orders of five or more. contact us to arrange to a bulk discount.