DRY090 Filament Desiccant Canister

DRY090 Filament Desiccant Canister

Filament Desiccant Canister

-

Keep filament bone-dry with DRY090 — a reusable, power-free canister packed with 3A molecular sieve. It desiccates (removes and locks away moisture) rather than blowing around hot air. Perfect for maintaining dryness after true drying, and designed to last the life of your printer.

- True desiccation – Physically adsorbs water molecules; heat ≠ dry.

- Infinite regeneration – Heat to 360 °C × 1 h or 240 °C × 4 h .

- Power-off protection – Works 24/7 in sealed storage; we ship filament dry, this keeps it dry.

- AMS-optimised – A full set of four (360 g total) can hold ~0% RH for months (opening-frequency dependent).

- Universal fitment – Fits most filament spool centres (see sizing) and clips into ECO Spool 2 with integrated retention clips.

- When to regenerate – After the container has been closed a few hours to stabilise, if RH is still >15%RH, regenerate.

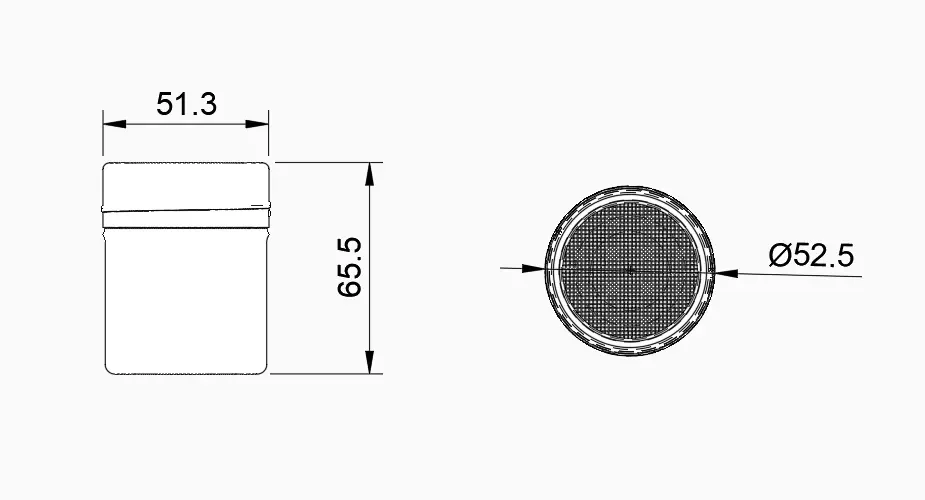

Model DRY090 Operation Passive desiccation (no power) Material Stainless housing, 3A molecular sieve Capacity 90 g per canister (up to 25 L sealed space) Regeneration 360 °C × 1 h (full) / 240 °C × 4 h (alt.) AMS Setup Up to 4 units (360 g total) Fitment Most spool centres; ECO Spool 2 clip-in Lifespan Infinitely regenerable (tested 300+ cycles) -

FREE SHIPPING in Australia for all orders over $80. Otherwise flat-rate postage of $11 applies within Australia.

Orders are shipped within 1 business day of order confirmation from our Sydney warehouse. You should expect your package within 2-8 business days upon receiving your dispatch confirmation. Read more.

-

14-day money-back guarantee on all orders. If you're not happy, we're not happy either. If you don't love our product, you'll get a full refund. Read more.

|

Materials |

304 Stainless Steel, 3A Molecular Sieve (Zeolite) |

|

Weight: |

90g ± 10g |

|

Temperature |

Zeolite: ≤600℃ | Stainless Steel: ≤870℃ |

|

Required Tools: |

None |

TECH SPECS

FAQ's

-

The DRY090 is a reusable desiccant canister filled with 3A molecular sieve — a high-performance drying material that actively removes and locks away moisture from the air inside your filament storage. This process, called desiccation, works with no power or moving parts, keeping your filament in print-ready condition around the clock.

-

If you care about getting perfect prints every time, 3A molecular sieve simply works better.

Holds more moisture per gram than silica gel, so it lasts longer between regenerations.

Faster action – starts protecting your filament immediately, even at very low humidity.

Stable at high temperatures – can be regenerated at 360 °C without damage.

Reusable for life – no performance drop-off after hundreds of cycles.

Silica gel degrades faster, absorbs more slowly, and often can’t handle high heat. With the DRY090, you buy once and keep your filament in print-ready condition for the life of your printer.

-

Many colour-change gels use cobalt chloride as the indicator — a chemical that can be toxic if heated. That’s why the DRY090 contains pure molecular sieve, no dyes, no toxins, and no risk when regenerating at the correct temperature. Instead of relying on a colour change, you work on a simple regeneration schedule — safer for you, your workspace, and your prints.

-

Most “powered dryers” are actually just full of hot air — they blow warm air around the filament to evaporate surface moisture. Heat alone does not guarantee truly dry filament, and many filaments require temperatures above their Vicat softening point to drive out deep moisture, which risks distortion.

The DRY090 works by desiccation — physically adsorbing and locking away water molecules inside its 3A molecular sieve. It keeps filament dry 24/7 with no power and no heat, even when your printer is off.

If you want powered desiccation for restoring already moisture-saturated filament, consider our professional STANDARD PRINT CO. Dry Cabinets, which use active humidity control to achieve and maintain true dryness safely.

-

In an AMS or multi-material system, a full set of four DRY090 canisters (360 g total) can keep humidity at 0% for months, depending on how often you open the unit. In a sealed spool or dry box, it lasts even longer.

-

Yes — and that’s one of its biggest advantages. The DRY090 is filled with industrial-grade 3A molecular sieve that can be regenerated an unlimited number of times without losing performance. With correct regeneration, it will outlast your printer.

Full regeneration: Bake at 360 °C for 1 hour to completely restore maximum moisture capacity.

Alternative regeneration: If your oven can’t reach 360 °C, bake at 240 °C for 4 hours. This drives out nearly all absorbed moisture and still returns the canister to high performance.

We’ve tested DRY090 canisters through 300+ full regeneration cycles with zero measurable drop in adsorption capacity. That’s centuries of protection under normal usage — no replacements, no ongoing consumable costs, just dry filament for life.

-

Molecular sieve has no colour-change feature. Instead, follow a schedule:

AMS / multi-material systems – Every 2–3 months.

Sealed spool storage – Every 4–6 months.

Regenerating more often is fine and won’t harm the sieve.

Use your storage humidity reading as your guide — but only after the container has been closed for a few hours to stabilise. If your sealed storage is still above 15% RH after that time, it’s time to regenerate your DRY090 canister.

Avoid taking a reading immediately after opening the container — fresh air rushes in and will give you a false high reading. Always close it, let it settle, then check.

-

Absolutely. The DRY090 works passively 24/7 with no power, heat, or moving parts, so your filament stays protected whether your printer is running or idle.

-

Yes. It fits most standard spool centres (see specs) and is purpose-designed to lock securely into the ECO Spool 2 using integrated retention clips.

-

All filaments are protected, but nylon, PVA, PETG, and TPU see the biggest improvement because they absorb water quickly. PLA and ABS also store more reliably in a low-humidity environment.