ABS Filament

Precision-engineered to combine uncompromising accuracy with unsurpassed toughness, impact resistance, and mild heat resistance. Our ABS filament is designed to perform in 3D printing applications with superior interlayer adhesion, bed adhesion and additional modifiers to minimise warping.

Whether you are prototyping for eventual injection moulding, fit testing or creating durable end-use products, switch to the new gold standard in ABS filaments.

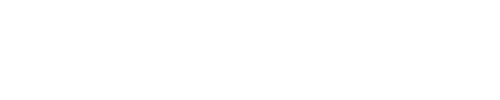

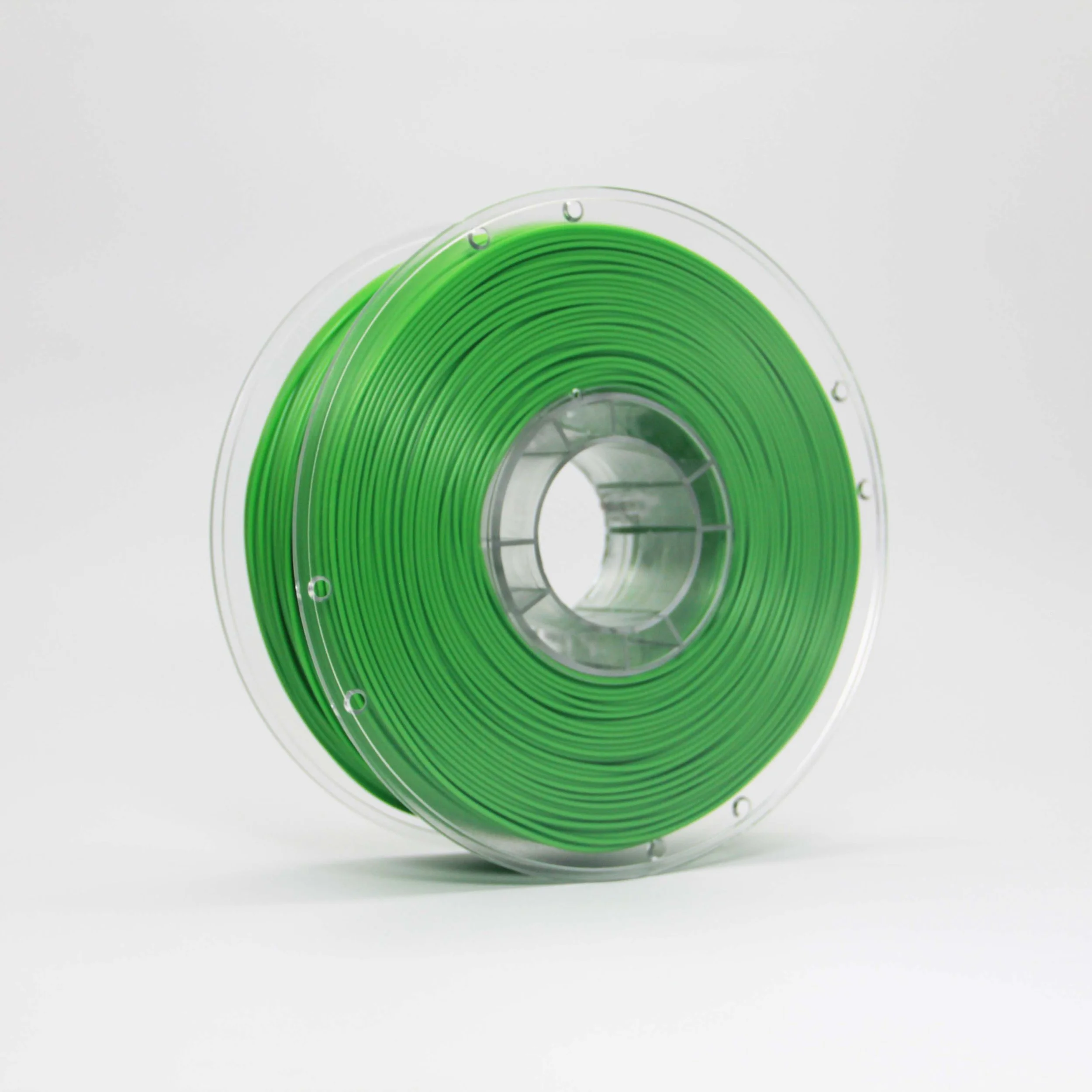

Available Colours

Black

Red

White

Orange

Natural

Yellow

Grey

Light Blue

Green

Lime Green

Purple

Brown

| Specific Gravity: | 1.05 g/cm³ |

| Tensile Strength (at yield): | 39.0 Mpa |

| Impact Strength : | 29.0 kJ/m² |

| Glass Transition Temperature: | 105°C |

| Surface Finish: | Matte |

| Transparency: | Opaque |

| Processability: | High |

| Spool | Packaging | Weight | Diameter |

| ECO | Reusable Spool | 1000g ± 1% | 1.75mm ± 0.03mm |

| Refill | Filament Refill | 1000g ± 1% | |

| 3000 | Single Use Spool | 3000g ± 1% |

Applications

Cases or Project Enclosures

Toys or Action Figures

Automotive Hardware

Mechanical Components

End Use Products

Functional Components

Tough and Durable

ABS has great impact resistance and moderate heat resistance (softening at around 105°C). This makes ABS ideal for 3D printing functional parts that need to withstand repetitive impact loading and moderate temperatures.

Large Composite Parts

ABS can be chemically bonded with acetone and super glue (cyanoacrylate). This allows large assemblies, made up of many smaller ABS parts, to be fused together - allowing you to produce parts far larger than what can be printed.

Accurate Prototypes

ABS plastic is a popular choice for prototyping by professionals as production prototypes can be printed in the same material as the final product. This allows for accurate prototypes that feel and behave the same as the final product.

Smooth Surfaces

ABS's ability to be dissolved in acetone also means that it can be chemically smoothed with acetone vapours to form a shiny, gloss surface finish. In this way, polished parts can be produced with almost imperceptible layer lines.

FAQ’s

+ When should I use ABS as opposed to PLA for 3D printing?

1. When you need something more durable and impact-resistant.

The ABS material is a bit weaker and softer than PLA, but it makes up for it by being able to withstand higher impact loads and bend before snapping.

| ABS | PLA | |

|---|---|---|

| Impact Resistance (kJ/m²) | ▲29 | 4 |

| Elongation at Break (%) | ▲45 | 4 |

| Tensile Strength (MPa) | 31 | ▲54 |

| Shore Hardness (D) | 76 | ▲83 |

2. ABS has a lower density than PLA making it better for lightweight applications.

With a lower density (1.03 g/cm³) compared to PLA (1.25 g/cm³), ABS is perfect for applications where minimizing weight is crucial.

3. When you need something to handle higher temperatures.

ABS has a higher glass transition temperature of 105°C compared to PLA's 65°C.

4. When you need to prototype a part for eventual injection moulding.

ABS is the material of choice for manufacturers when producing many consumer electronics parts and household items. 3D printing in ABS allows prototypes to be produced accurately in the same material as the final product.

+ How long do ABS prints last?

Keep ABS away from direct sunlight as it degrades quickly when subjected to UV rays. If kept under the correct conditions (under its glass transition temperature and not subjected to forces which would exceed its maximum yield strength), ABS parts will last for years.

+ Do I need a heated bed to print in ABS?

ABS must be printed on a printer equipped with a heated bed and an enclosure as a minimum.

+ Does ABS filament go bad?

Yes. To prevent your ABS from degrading, keep your material:

1. Out of direct sunlight

When exposed to sunlight for a prolonged period of time, ABS degrades.

2. In a dry environment with RH < 15%

Print resolution and interlayer adhesion may also suffer if your ABS gets wet.

3. In a cool environment < 105°C

Maintain a cool environment for your filament, well below its glass transition temperature, so that it maintains its roundness.

+ What print settings for printing ABS do you recommend?

A nozzle temperature of 240°C and a bed temperature of 110°C is a great place to start.

Downloads

ABS Filament Printing Guide - Coming Soon

Spending hours “dialling in” your slicer settings for the perfect print? Skip the guesswork with our FREE ABS 3D Printing guide.

Save time with advanced printing tips

Save filament and money with fewer failed prints

Gain the confidence to print larger and more complex models