Nylon Filament

A versatile and extremely strong 3D printing filament based on Nylon 6 making it resistant to high temperatures, oils and greases. Nylon's high impact strength and durability means post-processing is best done with tools meant for machining metals - albeit at lower speed. Due to the hygroscopic nature of nylon, filament storage in a dry box and drying before use is a must.

The perfect choice for rapid prototyping and production of tough, durable parts.

Available Colours

Black

Natural

| Specific Gravity: | 1.12 g/cm3 |

| Tensile Strength: | 37 Mpa |

| Impact Strength: | 10 KJ/m2 |

| Glass Transition Temperature: | 240°C |

| Surface Finish: | Glossy |

| Transparency: | Opaque |

| Processability: | Low |

| Spool | Packaging | Weight | Diameter |

| ECO | Reusable Spool | 1000g ± 1% | 1.75mm ± 0.03mm |

Applications

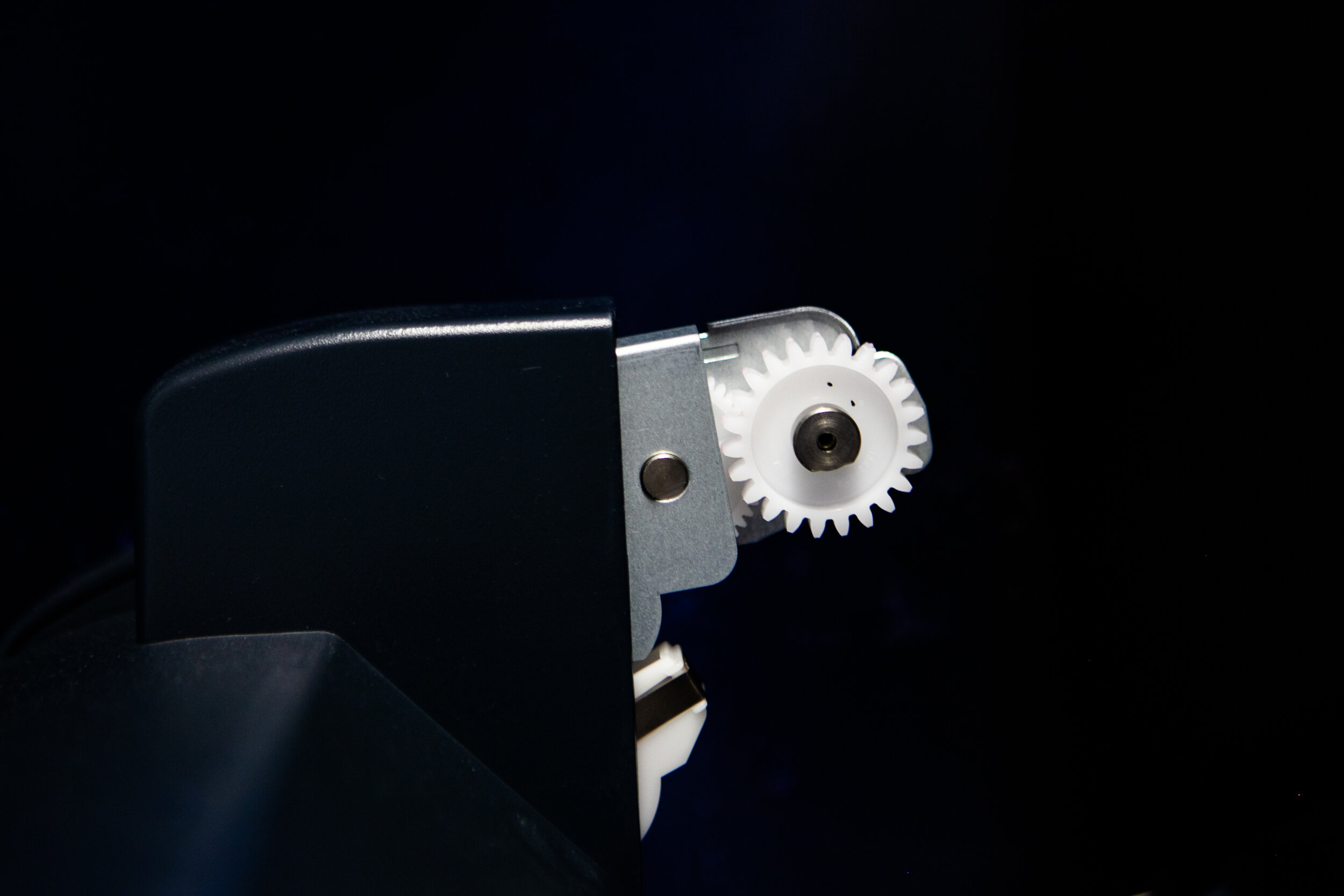

Gears

Screws, Nuts and Bolts

Cable Ties

Industrial tools, parts and jigs

Mechanical components

End Use Products

Casts

Temperature Resistant

Nylon's Vicat softening temperature is 180°C, which makes it a perfect material for parts that must withstand high temperatures.

Resistant To Greases

Take advantage of one of the most precise filaments available on the market and caputure detail down to the micon level for your models and mock ups.

Abrasion Resistant

Nylon’s low coefficient of friction and excellent abrasion resistance makes it great for 3D printed mechanical parts like 3D printed gears.

Impact Resistant

The tough, impact-resistant, and flexible properties of Nylon make it a good material for cases, enclosures, and snap-fit components.

FAQ’s

+ Why does my Nylon filament keep stringing?

Stringing is a sign that your nylon filament is wet.

Nylon is an extremely hygroscopic 3D printing material and will naturally absorb moisture (up to 2.9% of its own weight) from the surrounding air if left in an unsealed container. Printing wet filament results in 3D printed parts with poor surface resolution and will also significantly decrease part strength.

In order to restore your filament to printing to optimal printing condition you'll need to:

- Dry the filament

- Store the filament in a dry and airtight container

+ Why does my Nylon filament keep bubbling?

Bubbling is a sign that yoour filament is very wet.

Nylon is an extremely hygroscopic 3D printing material and will naturally absorb moisture (up to 2.9% of its own weight) from the surrounding air if left in an unsealed container. Printing wet filament results in 3D printed parts with poor surface resolution and will also significantly decrease part strength.

In order to restore your filament to printing to optimal printing condition you'll need to:

- Dry the filament

- Store the filament in a dry and airtight container

+ How do I dry my Nylon filament?

Nylon filament can be dried in one of two ways:

- Activley drying the filament - By heating in an oven or filament dehydrator at 100°C for 8 hours. Pay special attention not to exceed the suggested temperature and drying duration as doing so may lead to the filament deforming due to heat and affect the roundness of the filament. This can cause printability issues.

- Passively drying the filament - Storing the filament in dry conditions (< 15% RH) for 10 days will restore your filament back to a printable condition. A storage solution like our dryboxes are a great way to not only dry your nylon filament but will also allow you print directly from the drybox - keeping your filament dry and ready to go whenever you are ready to print.

Downloads

Nylon Filament Printing Guide - Coming Soon

Spending hours “dialling in” your slicer settings for the perfect print? Skip the guesswork with our FREE 3D Printing guide.

Save time with advanced printing tips

Save filament and money with fewer failed prints

Gain the confidence to print larger and more complex models